Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point in a pipe line. 304 stainless steel flanges offer very good corrosion resistance, and 316 stainless steel flanges have excellent corrosion resistance. Butt-weld flanges are also known as weld-neck flanges; the flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld. Slip-on weld flanges have no internal stop; slide a pipe through the flange and weld on both sides. Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through.Stub-end flanges are also known as lap-joint flanges; use them with a stub-end straight adapter (not included). The stub-end straight adapter slides into the flange and welds to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily for frequent cleaning and inspecting. Reducing flanges let you transition your piping system to a smaller pipe; attach to a flange with a larger pipe size but with the same flange dimensions. Cap flanges are also known as blind flanges.

|

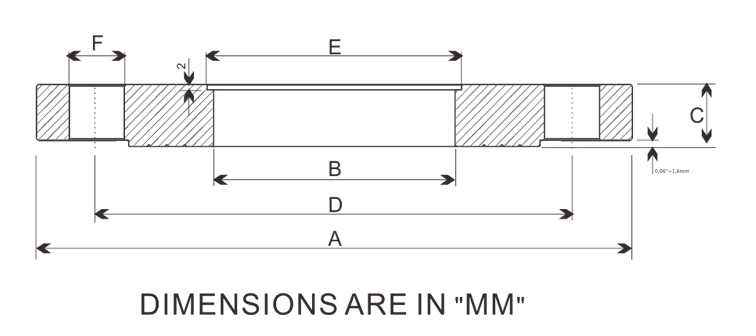

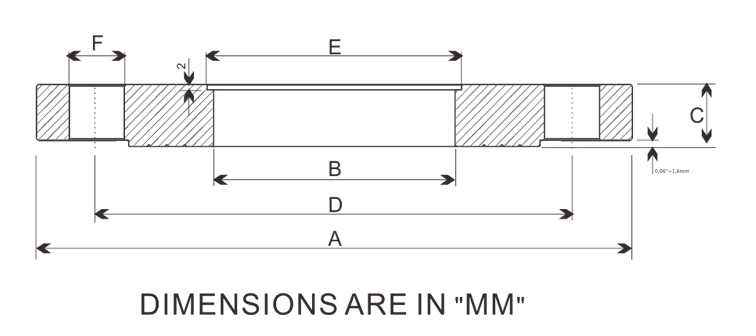

| Tube OD |

A |

B |

C |

D |

E |

F |

Part number 304 |

Price/each |

Part number 316L |

Price/each |

| DN15 |

95 |

16 |

14 |

65 |

19.5 |

14 |

SIG/99-DN15/304 |

TBD |

SIG/99-DN15/316L |

TBD |

| DN20 |

105 |

20 |

14 |

75 |

23.5 |

14 |

SIG/99-DN20/304 |

TBD |

SIG/99-DN20/316L |

TBD |

| DN25 |

115 |

26 |

16 |

85 |

29.5 |

14 |

SIG/99-DN25/304 |

TBD |

SIG/99-DN25/316L |

TBD |

| DN32 |

140 |

32 |

18 |

100 |

35.5 |

18 |

SIG/99-DN32/304 |

TBD |

SIG/99-DN32/316L |

TBD |

| DN40 |

150 |

38 |

18 |

110 |

41.5 |

18 |

SIG/99-DN40/304 |

TBD |

SIG/99-DN40/316L |

TBD |

| DN50 |

165 |

50 |

20 |

125 |

53.5 |

18 |

SIG/99-DN50/304 |

TBD |

SIG/99-DN50/316L |

TBD |

| DN65 |

185 |

66 |

20 |

145 |

70.5 |

18 |

SIG/99-DN65/304 |

TBD |

SIG/99-DN65/316L |

TBD |

| DN80 |

200 |

81 |

20 |

160 |

85.5 |

18 |

SIG/99-DN80/304 |

TBD |

SIG/99-DN80/316L |

TBD |

| DN100 |

220 |

100 |

20 |

180 |

104.5 |

18 |

SIG/99-DN100/304 |

TBD |

SIG/99-DN100/316L |

TBD |

| DN125 |

250 |

125 |

22 |

210 |

129.5 |

18 |

SIG/99-DN125/304 |

TBD |

SIG/99-DN125/316L |

TBD |

| DN150 |

285 |

150 |

22 |

240 |

155 |

22 |

SIG/99-DN150/304 |

TBD |

SIG/99-DN150/316L |

TBD |

| DN200 |

340 |

200 |

24 |

295 |

205 |

22 |

SIG/99-DN200/304 |

TBD |

SIG/99-DN200/316L |

TBD |

| DN250 |

405 |

250 |

26 |

355 |

255 |

26 |

SIG/99-DN250/304 |

TBD |

SIG/99-DN250/316L |

TBD |

| DN300 |

460 |

300 |

28 |

410 |

307 |

26 |

SIG/99-DN300/304 |

TBD |

SIG/99-DN300/316L |

TBD |

|

Giraffe Stainless products are warranted to be free from defects in material and workmanship for a period of one year from the date of shipment. Any product that proves to be defective shall be repaired or replaced at the option of Giraffe Stainless, providing it has been used as recommended and in strict accordance with recognized piping practices, and that has not been subject to extraordinary service, such as encountered under severe corrosive or abrasive conditions.

Giraffe Stainless makes no warranties, express or implied, other than those listed above.

Giraffe Stainless shall not be liable for any consequential, indirect, incidental or contingent damages.

Giraffe Stainless is a member of 3-A®, a voluntary organization committed to safeguarding public health and dairy product quality through a unique industry-regulated program of sanitary standards for equipment used in processing dairy foods.

Giraffe Stainless is a member of FISA, a national association of independent distributors and major manufacturers of sanitary supplies used in the food, dairy, beverage, pharmaceutical and personal care industries.

Giraffe Stainless is a member of FPSA, an association serving suppliers to the global food, beverage, and pharmaceutical industries